Praeparatio et proprietates spumae semirigidae polyurethanae pro manubriis autocineticis altae efficacitatis.

Bracchium in interiore currus pars magna est in cabina vehiculi, quod partes agit ianuam impellendi et trahendi, bracchiumque hominis in curru collocandi. In casu necessitatis, cum currus et manubrium colliduntur, manubrium molle polyurethani et manubrium e polypropyleno (polypropyleno), ABS (polyacrylonitrilo-butadieno-styreno) aliisque materiis duris modificatum, bonam elasticitatem et firmitatem praebere possunt, ita iniurias minuens. Manubria e spuma molli polyurethani sensum bonum et texturam superficiei pulchram praebere possunt, ita commoditatem et pulchritudinem sedis gubernatoris augentes. Ergo, cum industria autocinetica progressu et postulatis hominum de materiis interioribus emendatis, commoda spumae mollis polyurethani in manubriis autocineticis magis magisque manifesta fiunt.

Tria genera manubriorum molium polyurethaneorum sunt: spuma altae resilientiae, spuma auto-crustata, et spuma semi-rigida. Superficies exterior manubriorum altae resilientiae tegumento PVC (polyvinylchloridi) tegitur, interior autem spuma polyurethane altae resilientiae est. Sustentatio spumae relative debilis est, robur relative humile, et adhaesio inter spumam et tegumentum relative insufficiens. Manubrium auto-reticulatum nucleum spumae tegumenti habet, sumptus vilis, gradus integrationis altus, et late in vehiculis mercatoriis adhibetur, sed difficile est firmitatem superficiei et commoditatem generalem considerare. Brachia semi-rigida tegumento PVC teguntur, tegumentum tactum et aspectum bonum praebent, et spuma interna semi-rigida tactum, resistentiam impacti, absorptionem energiae et resistentiam senescentiae excellentes habet, ita magis magisque in usu interiorum autocinetorum privatorum adhibetur.

In hac dissertatione, formula fundamentalis spumae semirigidae polyurethanae pro manubriis autocinetorum designatur, et eius emendatio hac de causa investigatur.

Sectio experimentalis

Materia prima principalis

Polyether polyol A (valor hydroxylicus 30 ~ 40 mg/g), polymer polyol B (valor hydroxylicus 25 ~ 30 mg/g): Wanhua Chemical Group Co., LTD. MDI modificatum [diphenylmethani diisocyanas, w (NCO) est 25%~30%], catalysator compositus, dispersans madefaciens (Agens 3), antioxidant A: Wanhua Chemical (Beijing) Co., LTD., Maitou, etc.; Dispersans madefaciens (Agens 1), dispersans madefaciens (Agens 2): Byke Chemical. Materiae primae supradictae gradus industrialis sunt. Tegumentum PVC: Changshu Ruihua.

Instrumenta et apparatus principales

Mixtor celeritatis magnae generis Sdf-400, statera electronica generis AR3202CN, forma aluminii (10cm×10cm×1cm, 10cm×10cm×5cm), furnus electricus inflator generis 101-4AB, machina tensionis universalis electronica generis KJ-1065, thermostatus superpotens generis 501A.

Praeparatio formulae fundamentalis et exempli

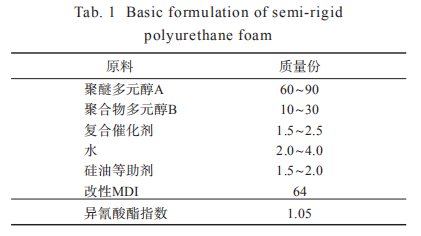

Formula fundamentalis spumae polyurethani semirigidae in Tabula 1 ostenditur.

Praeparatio exemplaris ad proprietates mechanicas examinandas: polyether compositum (materia A) secundum formulam designatam praeparatum est, cum MDI modificato proportione certa mixtum, instrumento agitationis celeris (3000r/min) per 3~5s agitatum, deinde in formam correspondentem ad spumam creandam infusum, et forma intra certum tempus aperta ad exemplum formatum spumae polyurethani semirigidae obtinendum.

Praeparatio exemplaris ad experimentum adglutinationis: stratum tegumenti PVC in inferiore formae formae ponitur, et polyether et MDI modificatum coniuncti proportionaliter miscentur, instrumento agitationis celerrimo (3000 r/min) per 3~5 s agitantur, deinde in superficiem tegumenti infunduntur, et forma clauditur, et spuma polyurethana cum tegumento intra certum tempus fingitur.

Examen effectus

Proprietates mechanicae: 40% CLD (duritia compressiva) secundum normam ISO-3386; Robur tensile et elongatio ad fracturam probantur secundum normam ISO-1798; Robur scissionis probatur secundum normam ISO-8067. Actio nexus: Machina tensionis universalis electronica ad cutem et spumam 180° detrahendam secundum normam OEM adhibetur.

Effectus senescentiae: Experire iacturam proprietatum mechanicarum et proprietatum nexus post 24 horas senescentiae ad 120℃ secundum temperaturam normam OEM.

Resultata et disputatio

Proprietas mechanica

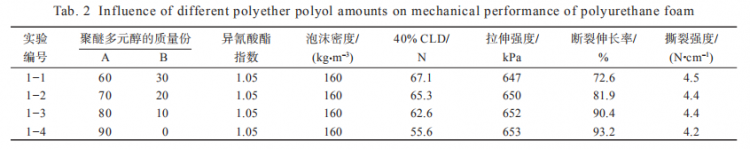

Mutando rationem polyetheris polyoli A et polymeri polyoli B in formula fundamentali, explorata est influxus diversae dosis polyetheris in proprietates mechanicas spumae polyurethani semirigidae, ut in Tabula II demonstratur.

Ex Tabula II apparet rationem polyetheris polyoli A ad polymerum polyolum B magnum effectum in proprietates mechanicas spumae polyurethanae habere. Cum proportio polyetheris polyoli A ad polymerum polyolum B augetur, elongatio ad rupturam augetur, durities compressiva quodammodo decrescit, et vis tensile et vis scindendi parum mutantur. Catena molecularis polyurethanae praecipue constat ex segmento molli et segmento duro, segmento molli ex polyolo et segmento duro ex vinculo carbamato. Ex una parte, pondus moleculare relativum et valor hydroxylicus duorum polyolorum differunt, ex altera parte, polymerum polyolum B est polyetheris polyolum acrylonitrilo et styreno modificatum, et rigiditas segmenti catenae propter praesentiam anuli benzeni augetur, dum polymerum polyolum B continet parvas substantias moleculares, quod fragilitatem spumae auget. Cum polyetheris polyolum A 80 partes et polymerum polyolum B 10 partes continet, proprietates mechanicae completae spumae meliores sunt.

Proprietas vinculi

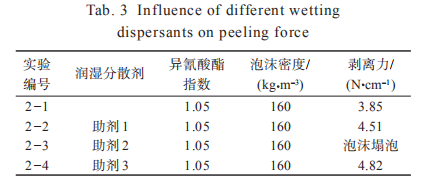

Ut productum cum frequentia pressionis alta, manubrium commoditatem partium insigniter minuet si spuma et cutis detrahantur, ergo vis nexus spumae polyurethanae et cutis requiritur. Fundamento investigationis supradictae, varia dispersentia madefacientia addita sunt ad proprietates adhaesionis spumae et cutis explorandas. Resultata in Tabula 3 monstrantur.

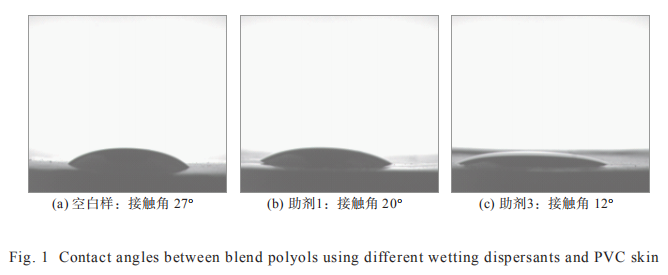

Ex Tabula 3 videri potest varia dispersentia madefacientia effectus manifestos in vim detrahendi inter spumam et cutem habere: spuma collapsa fit post usum additivi 2, quae fortasse ob nimiam aperturam spumae post additionem additivi 2 oritur; post usum additivorum 1 et 3, vis detractandi exempli inanis quodammodo aucta est, et vis detractandi additivi 1 circiter 17% maior est quam vis exempli inanis, et vis detractandi additivi 3 circiter 25% maior est quam vis exempli inanis. Differentia inter additivum 1 et additivum 3 praecipue causatur a differentia in humectabilitate materiae compositae in superficie. In genere, ad humectabilitatem liquidi in solido aestimandam, angulus contactus est parametrus magni momenti ad humectabilitatem superficiei metiendam. Ergo, angulus contactus inter materiam compositam et cutem post additionem duorum dispersentiorum madefacientium supradictorum probatus est, et eventus in Figura 1 monstrantur.

Ex Figura 1 videri potest angulum contactus exempli inanis esse maximum, qui est 27°, et angulum contactus agentis auxiliaris 3 esse minimum, qui est tantum 12°. Hoc demonstrat usum additivi 3 posse humectationem materiae compositae et cutis magis augere, et facilius eam in superficie cutis expandere, itaque usus additivi 3 maximam vim detrahendi habere.

Proprietas senescentem

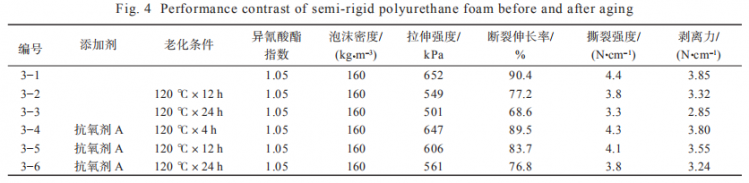

Manubria in curru comprimuntur, frequentia expositionis ad solem alta est, et facultas senescentiae est alia facultas magni momenti quam spuma semirigida manubrii polyurethani considerare debet. Quapropter, facultas senescentiae formulae fundamentalis probata est et studium emendationis peractum est, et eventus in Tabula IV monstrantur.

Comparando data in Tabula IV, inveniri potest proprietates mechanicas et proprietates nexuum formulae fundamentalis significanter imminui post maturationem thermalem ad 120℃: post maturationem per 12 horas, amissio variarum proprietatum praeter densitatem (eadem infra) est 13%~16%; amissio effectus maturationis 24 horarum est 23%~26%. Indicatur proprietatem maturationis thermalis formulae fundamentalis non esse bonam, et proprietatem maturationis thermalis formulae originalis manifeste emendari posse addendo classem A antioxidantis A formulae. Sub iisdem condicionibus experimentalibus post additionem antioxidantis A, amissio variarum proprietatum post 12 horas erat 7%~8%, et amissio variarum proprietatum post 24 horas erat 13%~16%. Diminutio proprietatum mechanicarum praecipue debetur seriei reactionum concatenatarum incitatarum a ruptura nexuum chemicorum et radicalibus liberis activis durante processu maturationis thermalis, quae mutationes fundamentales in structura vel proprietatibus substantiae originalis efficiunt. Ex una parte, detrimentum in effectu nexus ex declinatione proprietatum mechanicarum ipsius spumae oritur, ex altera parte, quia tegumentum PVC magnum numerum plastificantium continet, et plastificans ad superficiem migrat durante processu senescentiae oxygenii thermalis. Additio antioxidantium proprietates senescentiae thermalis emendare potest, praesertim quia antioxidantia radicales liberos novos eliminari, processum oxidationis polymeri morari vel inhibere possunt, ita ut proprietates originales polymeri conserventur.

Perfunctio comprehensiva

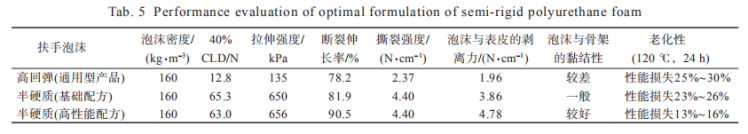

Hisce resultatis innixi, formula optima designata est et variae eius proprietates aestimatae sunt. Efficacitas formulae cum spuma generali polyurethani manubrii altae resilientiae comparata est. Resultata in Tabula V monstrantur.

Ut ex Tabula V videri potest, formulae spumae polyurethani semirigidae optimae quasdam habet utilitates prae formulis fundamentalibus et generalibus, et est utilior, et aptior est ad usum manubriorum altae efficaciae.

Conclusio

Polyetheris quantitate accommodata et dispersante madefaciente antioxidanteque idoneo electo, spumae polyurethanae semirigidae proprietates mechanicas bonas, proprietates optimas contra calorem senescendi, et cetera conferre potest. Ob spumae excellentem efficaciam, haec spuma polyurethanae semirigidae altae efficaciae materiis autocineticis, ut manubriis et mensis instrumentorum, adhiberi potest.

Tempus publicationis: XXV Iulii, MMXXIV